Come to think about the process of skiing, it's very interesting as many aspects related to the process of creating skiing such as physics, materials, and art. And it gives people different experiences and feelings. Thanks to the movie from Bloomberg and Wagner Custom Skis in Telluride, Co, it became easy to imagine how to build skiing.

Below steps are following to build skis according to "How Hand-Built Custom Skis Are Made".

Step 1: Drawing and Printing Design

First, drawing graphics, and printing out onto a piece of paper that's the full length of the ski using a very large-scale printer. That piece of paper goes into a press where the ink goes into the nylon top sheet material. Skis and snowboards is almost like canvas. It's amazing as people can express themselves on their own equipments.

Step 2: Preparing Cores

The cores are vertically laminated hardwoods. The core of the ski keeps the main structural layers which are either fiberglass or metal. A maple and ash will be used for the core. That creates a really heavy core that likes to hold an edge.

Snowboardmaterials.com shows type of ski cores here

Step 3: Cutting Cores by CNC Machine

Cores will go to the CNC machine. A router moves in three dimensions to shape cores. The CNC moves a very small knife and cuts the perimeter of the ski. It also cuts the base material. The base material is a very hard plastic.

Snowboardmaterials.com explain more about CNC Machine here

Step 4: Cleaning Off the Edge Part of Skies

The CNC machine can't completely cut through the core so it gets finished up by hand.

Step 5: Attaching the Steel Edges

The steel edges of the ski are attached by hand to the base material. Using some super glue and bend the edge really precisely to fit the base shape of the ski.

Steel ski edges are also sold online shops.

Step 6: Layout Process

All the individual parts of skis will be added and glued by resin together here until sandwich is constructed.

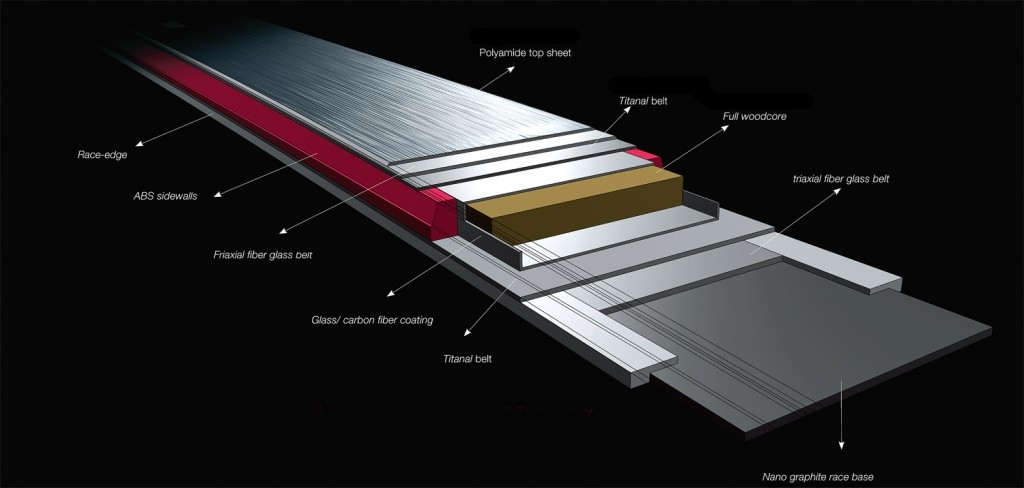

This is example of the layout from junksupply.com. According to junksupply,com, ski is layout topsheet, wood veneer or graphics, fiberglass, woodcore with some reinforcemand for the binding under foot and attached sidewalls, fiberglass, base with attached steel edges and VDS rubber from top.

And these materials are layouted and resin are added to attach.

Snowboardmaterials.com explain more about resinhere

Step 7: Pressing Skis

And then the skis are pressed using a pneumatic press. As the ski is pressed, all the excess resin is squeezed out of the ski.

Snowboardmaterials.com explain more about Ski and Snowboard press here

Step 8: Cutting Skies

After the press, the two skis are in a big block. This big block is cut in a band saw and skies are shaped. The band saw blade follows the steel edge, which keeps it from cutting the inner part of the ski. And the ski goes to the edger. The edger is a small, wet belt sander that bevels the edge of the ski to the customer's preference.

Step 9: Waxing

The ski gets waxed at this point. Waxing helps clean out any impurities left over from the finishing process. And then polish and buff the base at this point.

Step 10 : Pulling the Top Tape Off

and it's done!

And this is snowboard version. Snowboard is also mostly same as ski making.

And this is more Manufactural way